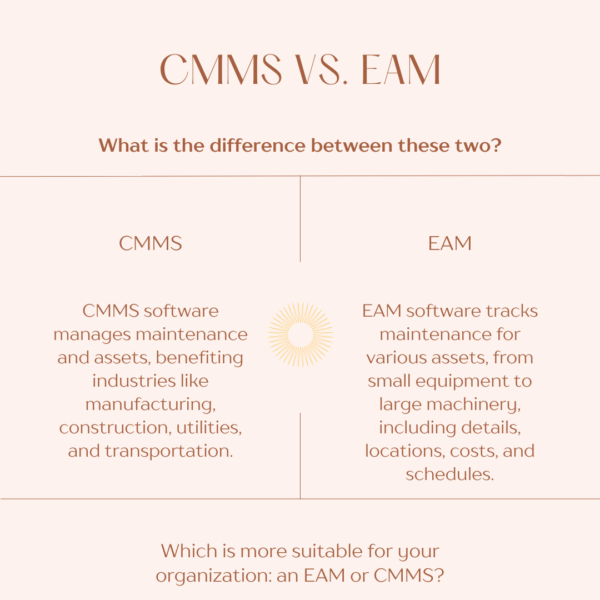

CMMS vs EAM, what Will Be Your Choice? Look at the trades and the headlines and you will find Enterprise asset management (EAM) software and computerized maintenance management systems (CMMS) as a realistic way to reduce expenses and increase revenues. Many regard EAM as CMMS on steroids and do not paint the true picture of it. Let’s look at the basic definitions of both of these streams, as well as some of the key differences between EAM and CMMS systems. Let’s see EAM vs CMMS!

What is EAM software?

Enterprise asset management software offers a more robust methodology for documenting equipment and its parts including warranties, schematics, and computer-aided design (CAD) drawings. Many of the benefits from enterprise asset management (EAM) software result from the ability to exchange data from other systems and subsystems despite these interfaces being not trivial in design or construction.

What is CMMS?

In general, CMMS deals strictly within the confines of the work order and preventive maintenance activity. The Preventive Maintenance Software schedules the work orders based on triggers such as hours of operation or timed events like every quarter/ year. It ensures probability-based availability of repair and spare parts. While it tracks and traces serial numbers, it also offers warranty and asset tracking.

With CMMS Software, the availability of manpower resources and maintenance teams with the required skills and training is assured. It maintains an asset registry and repair parts database (i.e. nomenclature, hierarchy structure, where used, support descriptions, etc.). Lastly, it also prepares statistical analysis of equipment performance and reliability while providing a variety of reports from static and dynamic sources.

What’s The Difference Between CMMS and EAM?

CMMS vs EAM

An EAM system adopts a comprehensive strategy and incorporates numerous business processes, whereas a CMMS concentrates on maintenance. EAM system may follow the whole asset lifecycle, beginning with design and installation, Whereas a CMMS only begins tracking after an asset has been acquired and installed.

Successfully utilizing CMMS and EAM systems

While CMMS and EAM, by definition, are different, they are often used together. Designers of manufacturing systems are not that short-sighted to think that every company has a Computer

Maintenance Management System (CMMS) or Enterprise asset management software. But they believe in a few basic questions to be answered.

- Where do the official inventories maintain?

- How will they keep inventories in sync?

- What will be the consequences if they go out of sync?

- Will they be able to put them back in sync?

The answers to these questions may dictate the need for CMMS or EAM software for your organization. The only thing to remember is that any process which helps you improve on what you are doing now is a good thing and should be considered.